We bottle multiple items in smaller lot; for the sake of our customers that strongly wish to develop their own private label products in absolutely not large amounts. We bottle 6-7 items on a production line per day: manufacturing high quality products in this system efficiently requires advanced technology, knowledge and experience that have been acquired over the years. Nowadays, as bottled beverage become common, it’s used as sales promotion means. In order to fulfill this needs, we have established both development technology and bottling system.

02. Strength in bottling multiple items in smaller lot: Manufacturing technology and capability of development

Manufacturing process

- Step1: Brewing

- Step2: Centrifugation / Filtering

- Step3: Mixing / Sterilization

- Step4: Filling up / Cap

- Step5: Overturning sterilizer

- Step6: Labeling

- Step7: Packing

- Step8: Anti-slip pasting / Printing carton

- Step9: Shipment

Our Factory

Water is the essence of all life, therefore we believe it has to be natural, good taste and safe: we make every effort to supply natural, high-quality and safe products. Our water source is at Kyohto district, Yamanashi Prefecture, where steep mountains and lushly green forest nurture fine underground water. We bottle and ship products using selected ingredients, through technology supported by passionate and highly motived water professionals, ensuring perfect quality control system.

- Yamanashi Factory

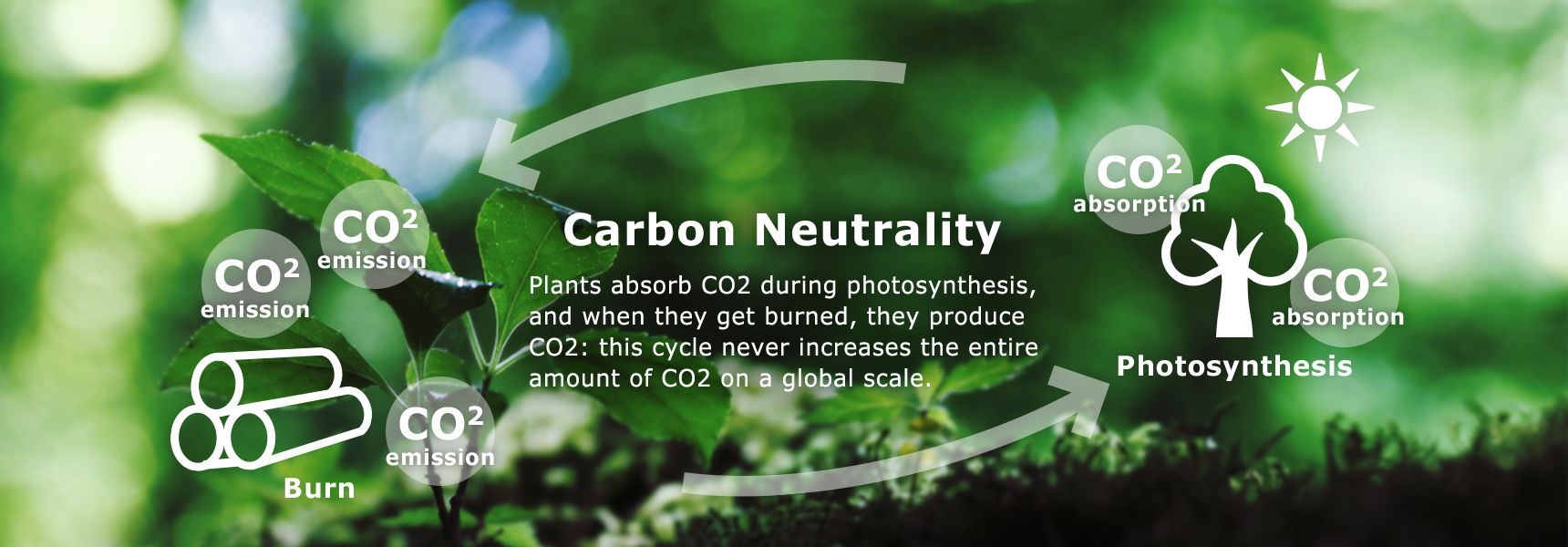

- Our oldest Factory since inauguration is surrounded by rich underground water vein near Takemori River in Enzan, Kohshu City. This environmental-friendly Factory consumes steam produced by biomass boiler as main heat resource, which had reduced 72% of fuel consume than regular Factory.

| Factory name | Yamanashi Factory ACCESS |

|---|---|

| Operation commencement | March, 1993 |

| FSSC 22000 authentication | Acquired on December, 2012 |

| Manufacturable items | Natural mineral water |

| Bottles | 500ml/16.9 fl oz 2L/67.6 fl oz 10L/338.1 fl oz (BIB) |

- Ishimori Factory

- Our second Factory was launched in order to meet our customers’ demand as well as aiming to take responsibility for keeping stable supply as a manufacturer.

| Factory name | Ishimori Factory ACCESS |

|---|---|

| Operation commencement |

July, 2004 |

| ISO authentication |

Acquired on June, 2009 |

| FSSC 22000 authentication |

Acquired on December, 2012 |

| Manufacturable items |

Green Tea, Oolong Tea, Barley Tea, Blended Tea, Isotonic Drink |

| Bottles | 2L/67.6 fl oz |

- Ono Factory

- Ono factory which had started operation from April 2019.

The factory is capable of bottling multiple items in smaller lots,

and aims to contribute to the local society as well. - Ono Second Factory

- Ono Second Factory dedicated to carbonated beverages started operation

in September 2023.

| Factory name | Ono Factory ACCESS |

|---|---|

| Operation commencement | April, 2019 |

| FSSC22000 authentication |

Acquired on March, 2019 |

| Organic JAS authentication | Acquired on March, 2019 |

| Manufacturable items |

Green Tea, Oolong Tea, Barley Tea, Blended Tea, Isotonic Drink, Natural Mineral Water |

| Bottles | 350ml/11.8 fl oz 500ml/16.9 fl oz 600ml/20.3 fl oz 1L/33.8 fl oz 2L/67.6 fl oz |

| Factory name | Ono Second Factory ACCESS |

|---|---|

| Operation commencemen | September, 2023 |

| FSSC22000 authentication |

Acquired on January, 2024 |

| Manufacturable | Carbonated water |

| Bottles | 500ml/16.9 fl oz/ 600ml/20.3 fl oz 1L/33.8 fl oz 1.25L/42.3 fl oz |

- PET Blow-Molding Factory 【Az-Bottle, Inc.】

- Some of our 2L/67.6oz PET bottles are blow and molded at our associate factory of Az-Bottle, Inc. The launch of this facility with Rotary method dramatically increased blowing speed: we built stable supply system of excellently thermostable bottles with low cost.

| Factory name | PET Blow-Molding Factory(Az-Bottle, Inc.) LINK |

|---|---|

| Operation commencement |

June, 2012 |

| Bottles | 2L/67.6 fl oz |